Portal Frame Factory:

Portal frame Factory:

Portal frames were first developed during the Second World War and became popular in the 1960s. They are now commonly used to create wide-span enclosures such as; warehouses, agricultural buildings, hangars, entertainment and sport venues, factories, large retail units, and so on, where a clear space is required uninterrupted by intermediary columns.

They were originally used because of their structural efficiency, meaning that large spaces could be enclosed with little use of materials and for a low cost. Tata Steel suggest that today, 50% of constructional steel used in the UK is in portal frame construction.

(Ref. SteelConstruction.info, Portal Frames.)

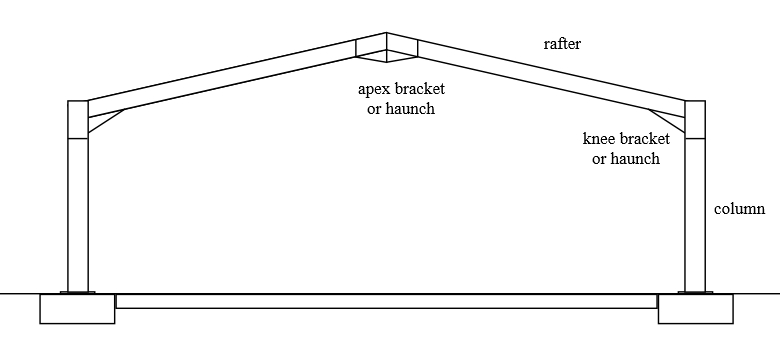

Portal frames are a type of structural frame, that, in their simplest form, are characterised by a beam (or rafter) supported at either end by columns, however, the joints between the beam and columns are 'rigid' so that the bending moment in the beam is transferred to the columns. This means that the beam can be reduced in sectional size and can span large distances. Typically, the joint between the beam and the columns is made 'rigid' by the addition of a haunch, bracket, or by a deepening of the section at the joints

Portal frames are generally fabricated from steel, reinforced precast concrete, or laminated timber sometimes referred to as 'glulam'.

Where a pitch is required, portal frames can have a mono pitch, or can have a double pitch with a rigid joint at the apex. Other forms include; tied portal frames, propped portal frames and multi-span portal frames which can cover very large areas. Where the portal frame includes a pitch, the wider the span of the frame, the higher the apex.

To reduce the overall height, a curved rafter might be adopted, or a mansard form. This can also help with water runoff, which can be significant on large roofs. A curved, or mansard form increases the pitch of the roof towards the eaves, where the runoff is likely to be at its greatest.

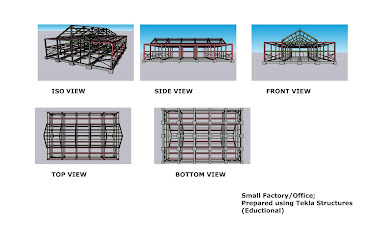

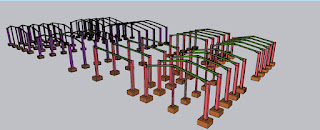

Generally, a building structure will be formed by a series of parallel portal frames running down the length of the buildings, typically 6 - 8 m apart. A secondary framework of purlins fixed to the rafters and rails fixed to the columns provides support for cladding. Portal frame structures are often clad with prefabricated composite metal panels, incorporating insulation. Masonry cladding may be provided at low level to give greater resilience and security.

They are a deceptively simple structural form, but care must be taken, particularly in the design of joints to ensure that appropriate restraint is provided to prevent buckling. Bracing is also required to give the row of parallel frames lateral stability, and this may be provided in an end bay or intermediary bay between the frames.

Portal frames can be a simple and rapid form of structure to erect, creating a wide, clear-span, weather-proof enclosure at low cost, with little material. They tend to be lightweight and can be fabricated off-site, then bolted to a substructure. The portal frames themselves may be left exposed to the internal space, and if carefully designed can be very beautiful.

Comments